"From concept, to designing an idea, to prototyping, to testing to see if it'll work, it's all done here:" an exclusive insight into how Belkin builds its products

I took a visit to Belkin's Global HQ to discover what makes its products so special

Get all the latest news, reviews, deals and buying guides on gorgeous tech, home and active products from the T3 experts

You are now subscribed

Your newsletter sign-up was successful

Like many of the largest tech companies in California, Belkin started out of a garage, back in 1983. Today, it’s one of the biggest names in mobile and computer accessories and peripherals on the market, and its global headquarters in Los Angeles is only a few miles from where it first started.

To find out what makes Belkin products different, I took a visit to its California lab for an exclusive look around. This is where new products are conceived, developed and rigorously tested before going to market. A mixture of boundless enthusiasm and relaxed Southern Californian attitude is part of the culture here, and the firm lives by a people, planet, product philosophy that guides everything it does.

In this one single space, a Belkin product goes from a concept to being tested with real people, to a designed idea, to prototyping, to testing to see if it’ll work. Then, after the factories have built it, it comes back here for testing again. “It’s very rare,” says Jen Wei, Vice President of Communications and Digital Marketing at Belkin International. “I’m sure it’s done in other industries, but I haven’t seen it in our space … sometimes we’re not sure if the consumers really appreciate all that goes into it.”

Having all of these functions in one space allows the teams to work adeptly and efficiently. According to VJ (Vijendra) Nalwad, Vice President of Engineering and Quality at Belkin, the process allows engineers to fail early, often and cheaply. “We know it’s inexpensive to recover and pivot. We can also try a lot of different things very inexpensively.”

The Belkin lab

Lab-made

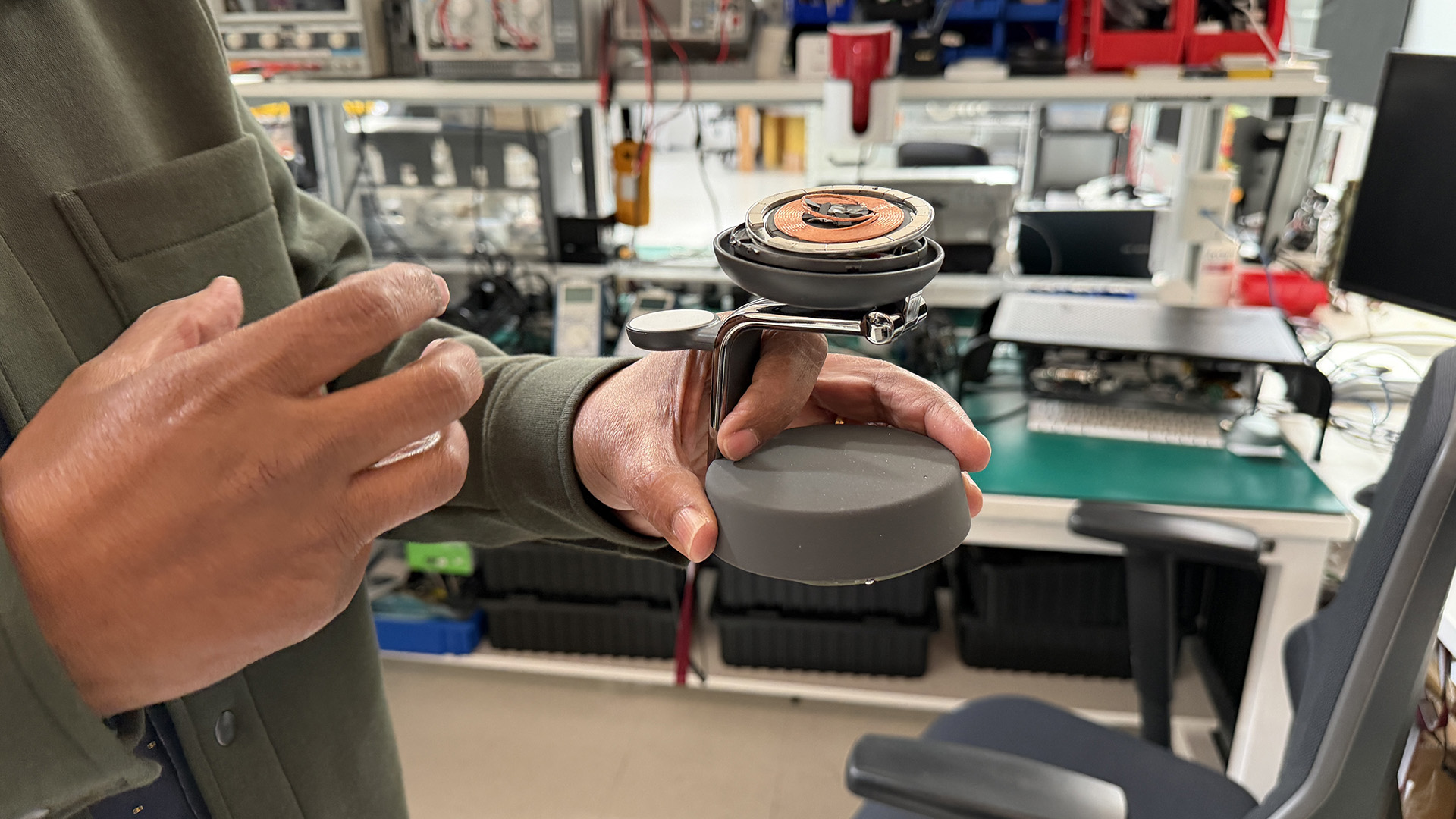

Inside the lab, rows of desks are covered with strange contraptions and product parts. An original testing machine for USB-C cables sits close by. This was built by the Belkin engineers, as nothing like it existed when they first started work on USB-C cables.

There’s an array of equipment here to allow the engineers to do all the testing they need, without slowing down the innovation process. Some of it is made in-house, while other bits of machinery come from other companies, like a device used to test wireless chargers, also used by the Qi certification lab. This means the products are more likely to pass first time, by the time they get to the certification level.

An environmental test room tests extreme conditions that the products and packaging are likely to be put under. Meanwhile, an accelerated testing process allows them to test in weeks how a product is likely to behave over years of use.

Get all the latest news, reviews, deals and buying guides on gorgeous tech, home and active products from the T3 experts

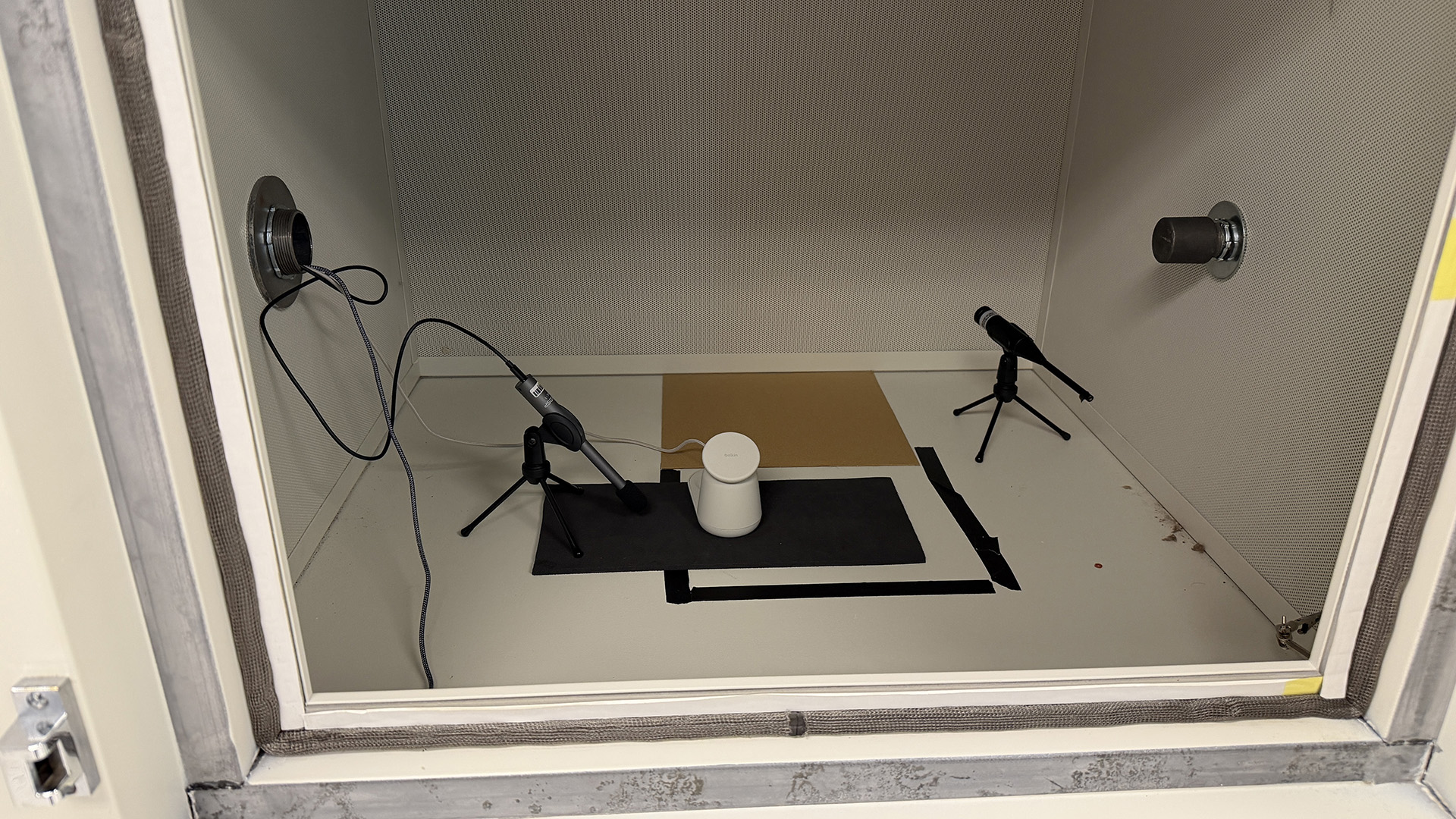

Acoustic testing at Belkin

Acoustic testing is designed to detect any high-pitched whines from chargers. Faraday cages provide Electromagnetic Interference testing, while another device tests for the dangers of electrostatic discharge. “Humans can carry a very high charge, easily 10,000 volts, says Stu Bush, Belkin’s Senior Director of Product Quality Engineering. “And it turns out anything over 100 volts can destroy a lot of integrated circuits (ICs).”

Other machines are designed to test the strength of screen protectors, drop tests for all sorts of devices, and a tumbler test to mimic keeping your phone in a pocket or bag with lots of foreign objects to test scratch resistance.

From concept to creation

A single product can typically take between three and eight months to pass through all stages of the design process before it’s ready to be shipped, while more complex products can be longer still. “It really depends on so many factors,” says Bush. “Belkin has such a wide spectrum of different products, and sometimes there are interdependencies, if we’re waiting on a spec, like a USB-C spec.”

To make early product mock-ups, Belkin’s innovation room has its own state-of-the-art 3D printer. These 3D models can then be placed in the paint booth to create a realistic finish, colour or texture to help get a better feel for the product.

There’s even a fully-fledged wood shop to allow the engineers and designers to carve their designs out of wood, foam or any other material before they start working on the CAD designs. “Often, if there are mechanisms, it’s easier for Engineers to just use their hands to create different linkages and put them together to see the mechanism work,” says Nalwad.

Packaging for Belkin is as important as the product, so in the packaging engineering lab, they pay as much attention to how the box looks and performs as the product itself. There’s a giant printer capable of producing one-off packages and a mockup shop rail in one corner, where they can see how they look when hung up.

Sustainable solutions

Back in 2019, Belkin set itself a target of reducing the single-use plastic in its packaging by 25% by 2025. By 2020, it had already reduced that by 50%, and today it's around 87%, with all new product lines in the last two years being 100% single-use plastic-free. This all contributes to its goal of being completely carbon neutral by 2030.

The Belkin Global HQ building is already extremely carbon-friendly. The space features 285 solar panels on the roof, walls of plants fed by stored rainwater, an efficient HVAC and lighting, plus electric chargers for cars.

Testing doesn’t stop once the product is completed at Belkin, either. The first 100 products that are returned go back to the lab for testing, so the engineers can check if it’s something they missed. “We look at them and say, okay, why are they failing?” Says Bush. “90% of the time, they don’t fail at all. It’s because there’s buyer’s remorse, or an unwanted gift, but about 10% of the time, we can find something we need to fix.”

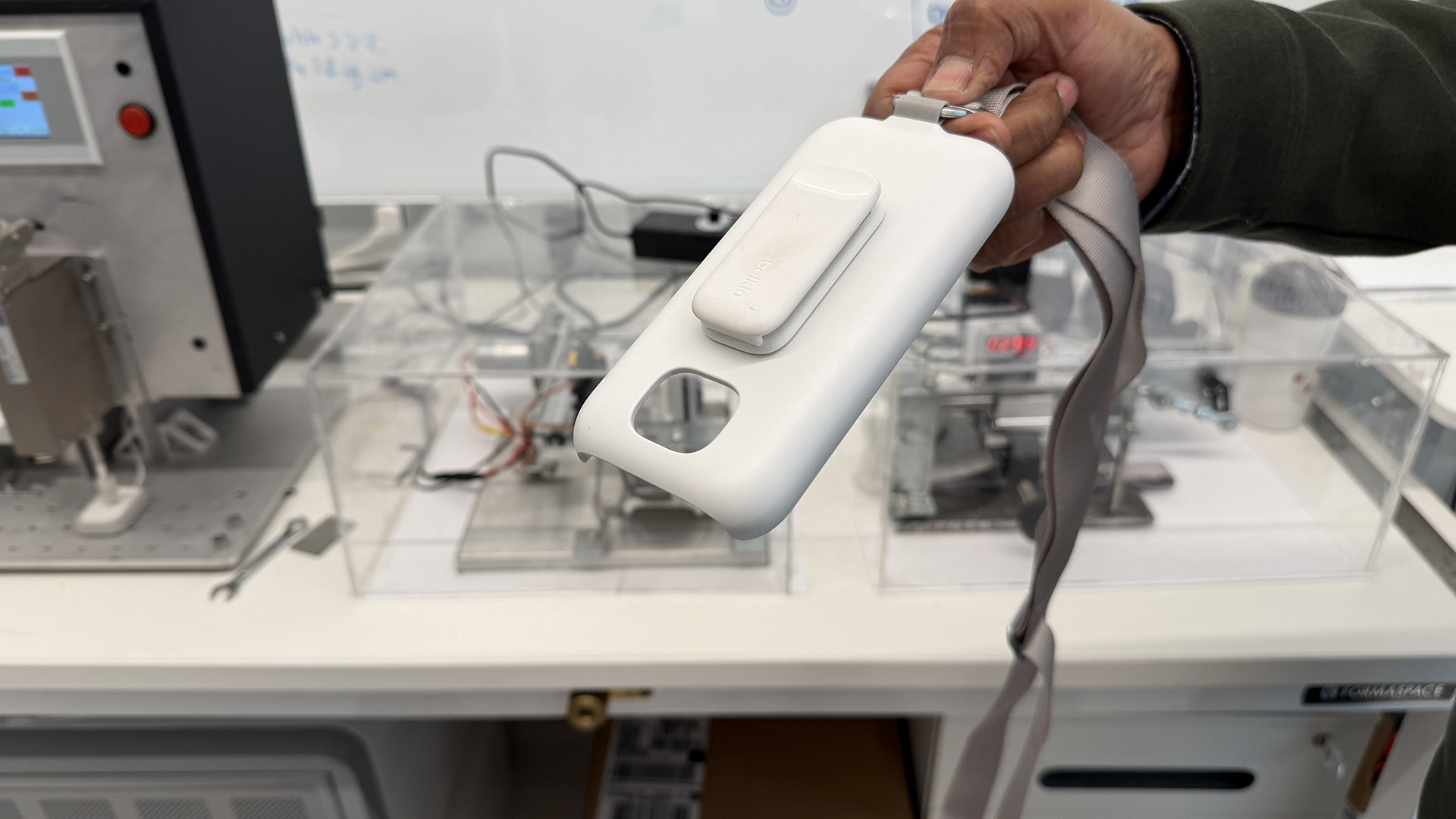

This all falls into Belkin’s continuous improvement, which will either influence a product update or the next generation of product, depending on the severity. In the reliability lab, products are put through repetitive tests to simulate long-term usage, whether it’s opening the clip on the Belkin Battery Holder for Apple Vision Pro or inserting a USB cable into a port hundreds of times.

The final room I’m shown is for product verification testing. Here, products are checked for compliance, compatibility, functionality, performance, as well as any marketing claims, much as any product tester of Belkin products would do. “If we make any marketing claim, like we can charge your phone 50% in 30 minutes, we’ll test that here,” says Ernie Roberts, head of global sustainability for Belkin.

What comes next?

At this year’s CES, Belkin released its latest range of power banks, wireless chargers, gaming cases, hubs and adapters. The new Charging Case Pro for the Nintendo Switch 2 builds on the original model to combine a power bank and stand into the carry case for those looking to game on the move.

Among the three power banks is an UltraCharge Pro Laptop power Bank, with a 27,000mAh battery to provide up to 240W of power to keep devices like the MacBook Pro 14-inch fully charged. While the UltraCharge Modular Charging Dock is the first 3-in-1 charger to support Android smart watches, thanks to a set of adapters that can hold watch pucks for Samsung and Google watches.

Belkin's product lines continue to impress, with some of my favourites being the 3-in-1 UltraCharge docks, which continue to get better with each generation and now offer 25W charging. Also, devices like the iPhone Mount with MagSafe for Apple TV 4K or for Mac Notebooks, which feel like a natural extension of the Apple ecosystem.

This is all possible thanks to the continued innovation that takes place at Belkin Global Headquarters. It’s what keeps the company ahead of the game and gives users confidence in its products. I can’t wait to see what comes next.

As T3's Editor-in-Chief, Mat Gallagher has his finger on the pulse for the latest advances in technology. He has written about technology since 2003 and after stints in Beijing, Hong Kong and Chicago is now based in the UK. He’s a true lover of gadgets, but especially anything that involves cameras, Apple, electric cars, musical instruments or travel.

You must confirm your public display name before commenting

Please logout and then login again, you will then be prompted to enter your display name.