Formula One technology that’s made its way off the track

Tech that was first pioneered in F1 can now be found in cars, bikes and even fishing rods

Commuting to work in a lacklustre run-around, you may think your life is far removed from the likes of Lewis Hamilton or Sebastian Vettel with their multi-million pound cars and jet-set lifestyle.

But your car probably already shares some technology with the finely-tuned machines that race around famous circuits, in the form of ABS brakes and on-board computers.

As Formula One technology continues to make its way off the race track and speed into everyday life, here are some surprising ways its's being used, from supercharging hospitals to boosting the efficiency of fridges.

- F1 2018: the ultimate TV setup starts with Sky Q

The McLaren S-works Venge

Jenson Button and Mark Webber both enjoy cycling, and F1 car manufacturers such as Ferrari and Mercedes are now designing bikes.

McLaren's S-works Venge carbon fibre racing bike is claimed to be the fastest road-racing bike in the world. While its frame weighs less than 960 grams, it is its aerodynamic design that makes it stand out from the crowd.

Californian bike brand Specialized, which co-developed Venge, used McLaren's F1 car design approach to model the bike, in order to study how the design would interact with a rider and the ground, even before a prototype was built.

Get all the latest news, reviews, deals and buying guides on gorgeous tech, home and active products from the T3 experts

It then tested the design in its wind tunnel, honing low aero drag features such as a truncated head tube and integrated stem.

Greener cars

Kinetic Energy Recovery Systems (KERS) were used in Formula One to collect wasted energy from braking and store it for later use. While this technology is now banned on the race track, it's used in most modern cars.

Williams Advanced Engineering developed electric flywheel technology, which allows some Audis and Porsche models to save fuel.

The firm has also played a role in making hybrid cars sexier by teaming up with Jaguar to make the C-X75 hybrid supercar, as seen in the James Bond film, Spectre.

Developed and launched in just 18 months, it produces CO2 emissions of less than 99g/km and can drive for 31 miles (50km) on electric drive alone, while retaining the ability to go from 0-60mph in less than three seconds and drive at more than 200mph.

Supercharged hospitals

Speed is of the essence, not only when comes to racing round a track but in saving lives. McLaren uses hundreds of sensors to collect and analyse real-time data during a race to give it the edge. Now this technology is being trialled in Birmingham Children's Hospital so patients can be monitored continuously and doctors alerted to any worrying signs.

In the first of its kind RAPID project, patients wear sensors attached to their chests and ankles to measure their heart rate, breathing rate and oxygen levels, which are processed in real-time using McLaren's data analytics platform, LIFEINSIGHT.

This technology means that signs normally recorded every one to four hours on paper charts could potentially become a thing of the past, with continuous individual monitoring that gives more accurate information helping lead to faster treatment – saving lives and reducing hospital stays.

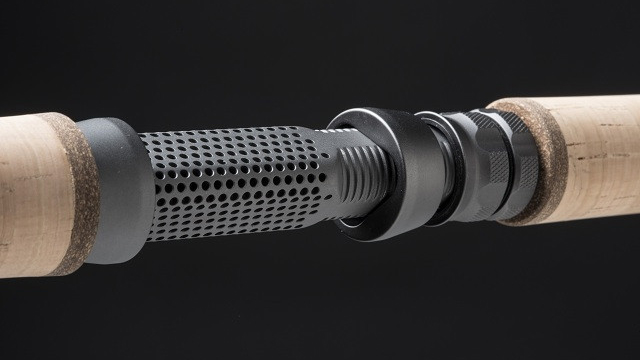

Formula One fishing rod

Fishing may seem the least-likely sport to benefit from Formula One Technology. But ex-Nasa scientist Gary Savage, who was the winner of three F1 drivers' and three constructors' World Championships used Formula One engineering know-how to create the Mackenzie FX1 graphene fly rod – a double-handed rod for catching salmon.

A specialist in composite technology, Professor Savage incorporated carbon fibre, used in many racing cars and graphene into the rod. Graphene is 200 times stronger than steel and the thinnest material known to man at just one atom thick, so its properties enable the rod to be strong, light and flexible. It is, however, currently banned in the construction of Formula One cars.

Less greedy fridges

Making the most of power in F1 cars is essential on the track, but Williams Advanced Engineering teamed up British start-up Aerofoil Energy to develop an aerodynamic device capable of making supermarket fridges more efficient.

It's designed to be attached to each shelf of an open-fronted fridge, to keep more of the cool air inside when the unit is opened by shoppers.

Williams engineers used computational fluid dynamics to model and simulate the new designs before testing them out, just as they would when designing a Formula One car.

Not only would a roll-out of the freezer-friendly device save supermarkets money, it would have environmental benefits, not to mention stopping shoppers from shivering in the freezer aisles.

Hi-tech toothpaste

Formula One pit stops may take less than three seconds, but they encapsulate the precision and teamwork the sport is known for. The same skills have been applied to a toothpaste factory in Maidenhead to boost speed and efficiency on the production line.

McLaren experts worked with GSK to minimise time lost at changeover, when factory workers swap from making one product to another. They made a computer model of the production line to simulate the process and used other methodology needed to choreograph pit stops, to cut the changeover time from 39 minutes to just 15.

This resulted in GSK's ability to fill an extra 6.7million tubes of toothpaste per year, and more importantly, the flexibility to change lines twice as often without losing any production time.

Winning sports teams

Telemetry systems collect more than one billion pieces of data from hundreds on sensors on a Formula One car in just one racing weekend, giving engineers and strategists a wealth of information with which to give their team the edge.

The technology has been used to train UK athletes in disciplines such as canoeing and bobsleigh, where sensors can be embedded into equipment.

The instant data enables athletes to make better decisions, hone their technique and develop faster than they would without the extra knowledge, to increase their chances of winning.

The technology was used by McLaren to hone the design of the UK team's bobsled, with Ferrari using a similar strategy for Italy.

Better run-arounds

Over the years, Formula One has given bog-standard cars ABS brakes, traction control, tyre pressure sensors and in some cases, carbon fire.

Sports cars often have light-weight bodies inspired by F1 cars as well as technologies such as flappy-paddle gear boxes, and adjustable suspension, which was developed for F1 over a decade ago.

And when all this technology goes wrong, mechanics plug a diagnostic computer into the car's electronic control unit to detect any problems. The computers were also developed for Formula One and are now commonplace across the whole auto industry.

Predicting the future

McLaren has joined forces with KPMG to apply the decision support tool it developed for its Formula One strategists - which lets them pick the best course of action in a race - to businesses to help people make the best financial decisions.

The tool can simulate and predict the outcome of high-stakes decisions before people make them, or boost performance in operations so groups of workers function like a pit stop crew.

A journalist with 10 years experience, Sarah specialises in Science and Technology, writing for the BBC, national papers and consumer magazines, including T3, of course. Sarah has reviewed a range of products for T3, from children’s electric toothbrushes to water bottles and photo printing services. There's nothing she can't become an expert in!