Forget the air fryer, my ultimate home appliance is robot sandwich maker

Putting a range of fillings between two slices of bread is something no tech has managed to replicate, until now

Get all the latest news, reviews, deals and buying guides on gorgeous tech, home and active products from the T3 experts

You are now subscribed

Your newsletter sign-up was successful

Forget the best air fryers, multi-cookers and ice cream makers, the kitchen gadget I desire above all else is a fully automated sandwich maker. Not something that merely melts cheese and toasts bread but a super dextrous appliance that slices the bread, butters it, prepares the filling from raw ingredients, and delivers the sandwich of your life on a plate. It would be a spectacular piece of robotic theatre enlivening the home.

It could also transform the economy by boosting productivity. Britain munches its way through 4 billion sandwiches from retailers every year, an industry worth over 8 billion pounds, employing around 300,000 people. The firms involved find it very hard to recruit enough staff in today’s tight labour market. Labour accounts for up to 40% of the price of a typical meal deal sandwich. If only the whole process could be mechanised.

Alas, the goal has proved elusive. It’s not putting spread on the bread that’s a problem. Machines to do that, called “depositors”, have been around for over a century. They work by melting the spread and dripping it through a grille for even coverage. The challenge is picking up the variety of randomly shaped ingredients and placing them accurately and evenly on each slice.

Fortunately companies like Britain’s Industrial Robotic Solutions (IRS), are working hard to create robot sandwich-making devices. I visited them in their lab on the University of Essex campus where I witnessed their prototype, called Pronto, in action.

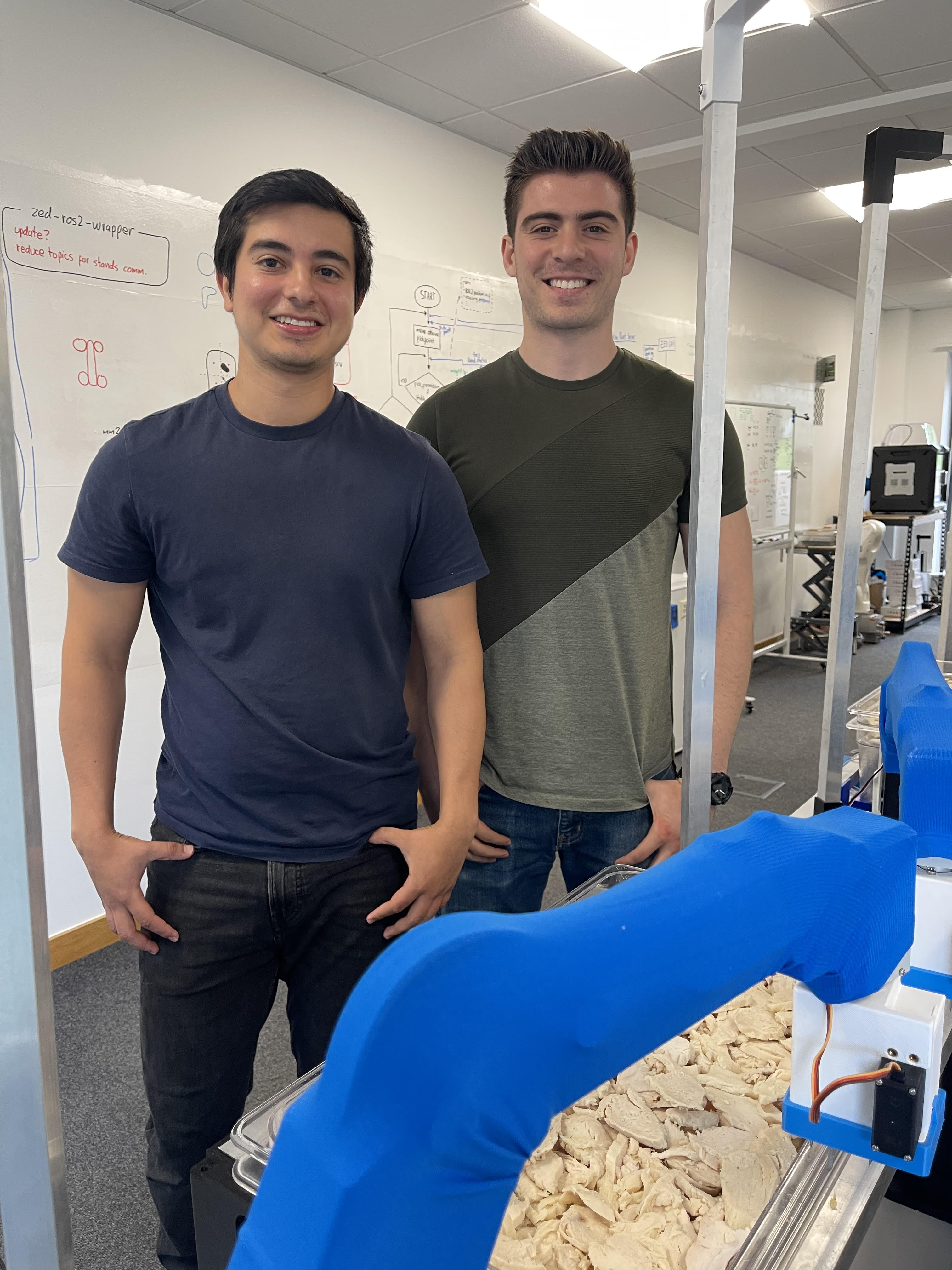

Pronto Chief Technical Officer Rodolfo Cuan Urquizo (on the left) and Senior Robotics Engineer Antonio Rosales Medina (on the right)

I found the process mesmerising to watch as chicken sandwiches were accurately and speedily pieced together by a line of quietly balletic robot arms. Where most robots use finger grippers or suction cups to pick objects up, IRS Chief Technical Officer Rodolfo Urquizo, with the help of Innovate UK and venture capital funding, has developed a new and patented range of grippers that operate in different ways and can, it is claimed, pick up virtually any ingredient. Different ingredients require different heads and they’re easily interchangeable.

Cameras working with specially developed software help ensure each ingredient is picked up by its centre and placed accurately and delicately on the bread. The software makes the robots work together to fill in gaps. Founder and CEO Peter Schwabach likens the process to a game of Tetris with food. The system can also fully assemble burgers, deposit ingredients on pizzas, and assemble fruit salads -I’m assured it does a very good job of picking up the likes of grapes and melon cubes. All ingredients are weighed and the contents recorded.

I’m impressed that Pronto’s engineers are adapting readily available off the shelf robots, inexpensive cameras and standard conveyor belts. I like the way the system uses AI, and the falling price of computer power and robotic hardware, not to attempt almost impossibly difficult tasks like driving a car on public roads, but to perform simpler, more routine ones, more effectively.

Get all the latest news, reviews, deals and buying guides on gorgeous tech, home and active products from the T3 experts

They’re testing Pronto inside a real sandwich factory in October and will go to market next year. Firms will be able to rent the equipment rather than stump up the capital cost. The robots could be revolutionising our lunch very soon. “In five years’ time people will say -did they really do this by hand?” enthuses Peter.

I, of course, want the domestic version. I can imagine my own mini production line in a corner of the kitchen with a circular conveyor belt, pots of ingredients and a bread dispenser, plus a robot head that changes with every rotation. It would put the coffee machine in the shade.

Jon is the main gadget reviewer and presenter for The Gadget Show on Channel Five. He was previously the Producer and Executive Producer of BBC's Top Gear between 1987 and 1999 and had a corner named after him on the Top Gear test track. He launched Fifth Gear for Channel Five and produced the show until 2004. When not presenting Jon enjoys writing. In 2019 Atlantic Books published his first book, Autopia: The Future of Cars, and he contributes regularly to Amateur Photographer magazine.