T3 visits Heineken’s Göss brewery and, yep you guessed it, we drink a dump truck load of beer

We also discover how the beer is made and how Heineken has made Göss the world’s first carbon-neutral, large-scale brewery

To celebrate International Beer Day T3 has republished this classic article that details what happened when T3 visited Heineken's Göss brewery - here's a hint: we drank A LOT of beer. If you would prefer less of a continental beer, however, then why not check out this classic Man vs Tech where we go hands on at a British brewery in the creation of our very own top T3 tipple.

Beer, it's great isn't it? Well, here at T3 Towers, we certainly think so, which is why we jumped at the chance to take visit to Heineken'sGöss brewery in Austria.

Göss beer is renowned throughout Austria and Europe (there's a damn good chance you've already tasted one of its products), however now this brewery is becoming known for its environmental credentials as much as its beer. The main reason? TheGöss brewery is the world's first large-scale brewery that is completely carbon neutral.

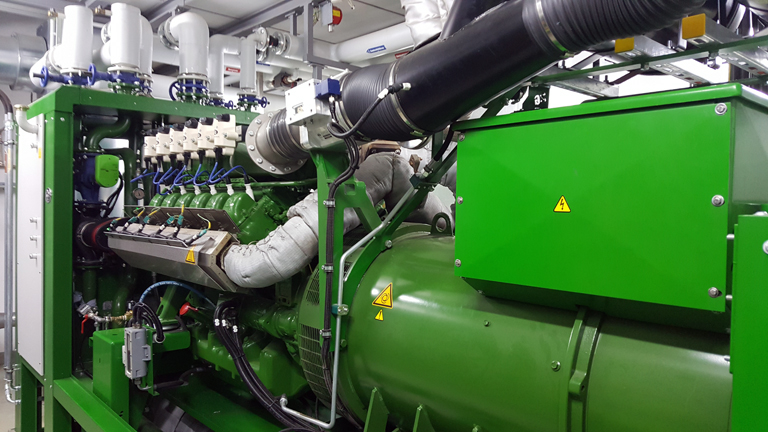

Not only is the brewery carbon neutral, but it has also been awarded two EU Sustainable Energy Awards. This is because the traditional brewery is now powered entirely by renewable and reusable energy sources, including a green quartet of solar, hydropower, biogas and waste heat.

The chance to go and see how beer is produced, as well as take a closer look at the technology that has helped the brewery to become carbon neutral? Not to mention drink our own body weight in fine beer? No brainer really.

The spectacular view from the top of theHeineken's Göss brewery, Austria

TheGöss brewery is located in the rural city of Leoben, Austria. The brewery grew out of a dissolved monastery, which had been making beer since the Middle Ages and, from 1860 onwards, the site started producing the beer that it is now known for. In fact, by 1892 the site had quickly become the largest brewery in the Upper Styria region of Austria and turned out north of 60,000 barrels of beer a year.

Get all the latest news, reviews, deals and buying guides on gorgeous tech, home and active products from the T3 experts

Göss brewery grew out ofGöss Abbey andmonastery, which was shut down in the 18th century

Fast forward over a 100 years and theGöss brewery makes over a million barrels per year and employs 150 people, 57 directly working in the brewery. And, without putting too finer point on it,Göss needed to expand as it has done over the past 100 years or so as Austrians really do like their beer. How much do they like it? How does a combined total consumption of over nine million hectolitres per year sound? Crunching the numbers, that means that each Austrian drinks on average 100 litres of beer per year, every year.

Yowzers! That is a lot of beer.

TheGöss brewery Brew Master Andreas Werner, the man responsible for the site's impressive environmental credentials.

The man who has overseen this expansion at Gössover the last decade, as well as the chap who has spearheaded the brewery's quest to become carbon neutral, is Brew Master Andreas Werner. Asides from having the coolest job title in the world, Andreas is also the man responsible for overseeing the daily operation ofGöss, as well as tasting and critiquing the beer it produces.

A close-up of some old monastic buildings within the brewery's grounds

And, talking of beer, Andreas andGöss produce a lot of them. The brewery's most famous tipple isGösser, which after some solid tasting, we can confirm is a light, decently malty beer with a sharp taste. However, as Andreas was keen to demonstrate in the brewery's tasting room, theGöss brewery also produces GösserSpezial, a beer that was served at the gala dinner of the Austrian State Treaty in 1955,GösserStiftsbräu, a tasty dark beer with a smoky character, as well as the unfiltered and fruity Zwickl beer among many, many others.

A selection of beers brewed by Heineken atGöss and at breweries further afield

Naturally we took a bullet for you dear reader and drank them all, en masse. We can confirm thatGösser, but notably Spezial andStiftsbräu, are beers you should most definitely search out. All theGöss beers are made from locally sourced Austrian materials and ingredients and, thanks to having such expertise as Andreas' behind each beer's formation, each manage to taste unique and, if we're being honest, a little old fashioned.

Brew Master Andreas Werner talks us through the wide selection of beer brewed at carbon neutral Göss

That old fashioned taste is a good thing and, as I soon found out, it partners up well with the entireGöss setup. Not only is the brewery at the heart of Austria's beer drinking public, but it is literally at the centre of Leoben and the local community too. Local people work in the brewery, Andreas himself lives a stone throw from its front gates and, when the Brew Master hit the town with us, it was like walking around with the city's mayor. It seemed as if everyone knew Andreas and numerous nods, hat tips and pleasantries were exchanged.

A close-up ofGöss brewery's famous beerGösser's logo, one of the largest and most well known in Austria

It became clear very rapidly that Heineken have partnered well here with Andreas. Not only does the man know how to make top beer, but he also has had a vision about how his brewery could partner its heritage with a very real need to modernise in terms of environmental impact.

Speaking to Andreas, as well as Michael Dickstein, Heineken's Director of Global Sustainable Development, it was evident that company is aware that existing operation models for breweries need to change, to become more sustainable and environmentally friendly, and withGöss they believe they have hit upon a role model.

The modernGöss brewery began operation in 1860, as this memorial stained glass window commemorates

Göss makes good beer, is now carbon neutral thanks to its adoption of renewable energy sources and practices and - crucially - still makes money. After all, these sort of modernisations not only require the vision - in this case provided primarily by Andreas - but also a solid and practical business model to achieve - there's no good making a brewery more sustainable if it means it goes out of business.

As Andreas was keen to point out, each brewery will have its own unique challenges to becoming carbon neutral or more sustainable, however he has shown that it can be done.

The "Sudhaus" or Brew House, home ofGöss' mash tuns

So how is the beer made?

In the brewery our first port of call was the Brew House, which was incredibly hot and humid. The reason for this is that this is where the brewery's mash tuns are located, huge vats in which a mashing process takes place to convert the starches in crushed grains into sugars for fermentation (referred to as wort). The plate heat exchangers in these tuns are powered by energy fromGöss' solar field and the tuns themselves are equipped with an automatic cleaning system - this is good as in the past real humans would have to crawl into the vats and scrub them clean with large brushes.

An antique copper mash tun. The modern tuns are powered by energy fromGöss' solar field

Traditionally the mash tuns were made out of copper, however today the site's numerous tuns are made out of steel, which gives them a cool, futuristic aesthetic. They're also rather noisy when they're on and going about their mashing business - that was cool though as it gave us chance to check out the Brew House's impressive control station.

Two of the modern, automatically cleaning, mash tuns in the impressive and hot Brew House

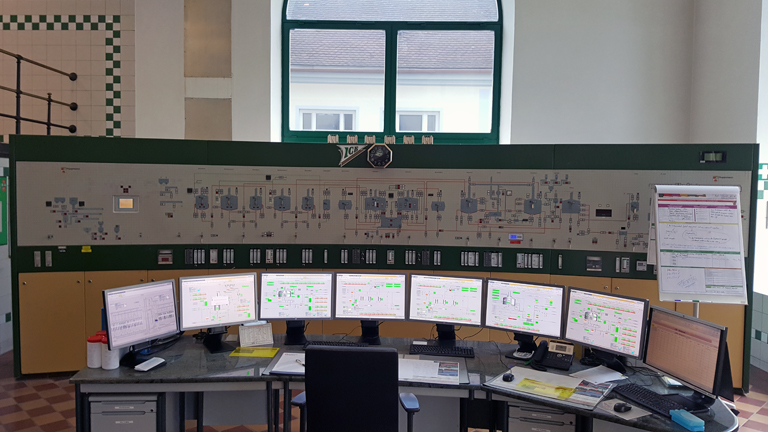

The Brew House's complex control station

From the Brew House we moved onto the brewery's fermentation plant, which as you can see from the numerous images below, was pipe-tastic and all a bit Willy Wonka's chocolate factory. In this facility over 57,000 pints ofGösser wort can be fermented with the brewery's "secret sauce" yeast, which is a process that occurs in the easily recognisable cone-shaped fermenting tanks.

Actually to say they are cone shaped is a little disingenuous, as while what you can see is cone shaped, the tanks actually extend vertically upwards above the ceiling. Each one of these tanks is seven metres (15 feet) tall and this helps generate pressure within, needed for the fermenting process, which takes an entire month.

The bottoms ofGöss's vertical fermenting tanks. These differ to Heineken's standard, horizontal tanks

Surrounding the fermenting tanks are a series of circular pipes filled with ammonia. Ammonia, which is super cold, helps keep the fermenting sugars in the wort - you need the sugars to ferment as they turn into the ethyl alcohol and carbon dioxide gas needed in beer - at optimal temperature. Interestingly, when one batch of wort has been fermented, the remaining yeast - which has gathered at the bottom of the tanks - can then be harvested and re-used. About 1.5 metres of yeast gathers at the bottom of each cone.

Beer in these tanks ferments for a month, with approximately 1.5 metres of "creamy" yeast accumulating at the bottom

And, when walking around the fermenting plant, it was obvious that whileGöss may be very old fashioned in its culture, architecture and relationship with its home city of Leoben, in terms of its beer-making processes it is very modern, with a plethora of complex machines working around the clock to produce its beverages. Everything was also incredibly, like almost laboratory clean, with shiny metal piping, floors and walls looking as if the entire plant had only been in operation since last week.

The yeast thatGöss uses for its beer is its "secret sauce" and never changes

I mean, seriously, just look at some of the nearby images - it's like a top secret military facility from a James Bond film or something. All pipes, knobs, dials, buttons, levers, tanks, control panels and noise. Yes, the fermenting plant was actually also incredibly noisy, with its myriad of machines and cold atmosphere adding to the laboratory feel.

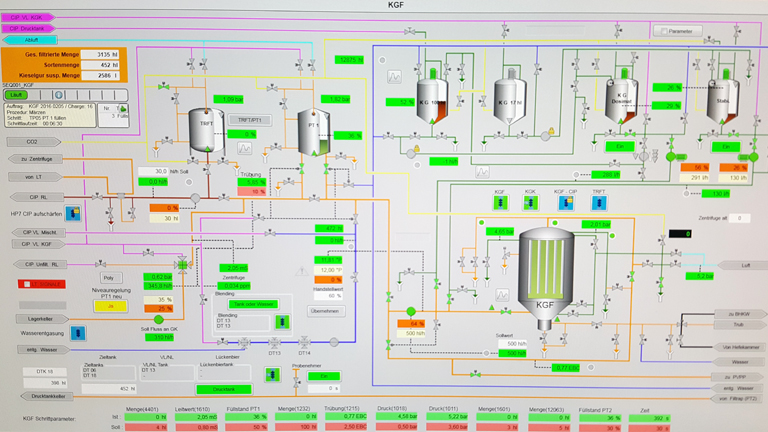

A close-up view of the fermenting tanks' control station

The fermenting tanks and wider area were monitored and operated via a dedicated control station, with a bank of screens showing the status of all components and processes during the current fermenting cycle. From the control station, Andreas then proceeded to take us into the final major installation actually in the central brewery buildings, the bottling plant.

The bottling facility atGöss, where 36,000 bottles can be processed per hour

Yes, as well as brewing and fermenting the beer on-site, and doing so with machines that are either totally powered or partially powered by renewable energy sources, such as that generated by its solar fields, excess heat generated by Leoben's nearby saw mill (which the brewery has a business relationship with), or via its adjoining BioGas plant (which we will come to next),Göss also bottles all its own beer. And, what's more, it manages to do so still with consideration for its environmental obligations.

Post bottling, every surface is meticulously washed to maintain cleanliness

The bottling plant can process 36,000 bottles per hour, despite it taking 30 minutes to clean every single bottle it uses. Of these bottles, due toGöss making the decision to use a 350-gram weight for its bottles, which is much heavier and sturdier than typical, it re-uses almost all of them, with any single bottle having an average lifespan of 20-50 uses. The bottles are also made locally in Austria.In fact, as Andreas is keen to point out as we look down on the bottling machines, only five per cent of bottles are lost outside of this usage average.

Oh, and while we are talking about the bottling plant machines, the high-tech bottle washer is completely powered by solar energy and long distance heat.

Göss' next-generation BioGas spent-grain fermentation plant, a key part in the brewery achieving its carbon-neutral status

Finally, moving away from the main brewery complex toward the site's solar field, we were taken to what isGöss' ecological high point - its own, dedicated, BioGas plant, which is a facility that takes spent grain and surplus yeast and breaks it down and converts it into usable biogas.

The plant consists of four units, a hydrolysis unit where the first stage of biological degredation takes place (the precursor breakdown of complex organic structures), a fermenter where carbohydrates, fats and proteins contained in the received substrate are broken down and converted into methane and carbon dioxide, a post-fermenter where the fermenter's produced biogas is cleaned of unwanted hydrogen sulphide, and a digestate storage unit, which provides additional gas storage of around 4000 m3.

Beside the BioGas plant lies the brewery's solar field

Thecool part about the BioGas plant, and why it is so invaluable to Andreas and Heineken's push at Gössto make the brewery as environmentally friendly as possible,is that from the post-fermenter the plant can feed this cleaned and dehumidified biogas into the brewery's existing steam boiler, or it can be converted in a gas engine to produce electricity and waste heat (which can be used to generate hot water).

Heat generated like this by the BioGas plant goes directly to the brewery, where it can be used to make hot water, which can then be used in things like the bottling plant's bottle washer, while any electricity generated is fed directly into the local grid.

The BioGas plant is never shut down, not even for maintanence, and can be interacted with remotely too

The result of all these technological advancements and processes is thatGöss' BioGas plant can process 16,000 tons of spent grain per year, can produce enough electricity to power seven per cent of all households in Leoben and, most importantly of all, helps the brewery "close the energy loop", feeding all its generated digestive back to the soils of Leoben's surrounding farmers.

Oh, and if that wasn't cool enough, the BioGas plant never needs to shut down, not even for maintenance, and can be operated either on-site or remotely.

The BioGas plant processes 16,000 tons of spent grain per year

And, having had a tour around the whole brewery, the surrounding town of Leoben and the beautiful landscape of the valley they are nestled in, we guess that "closing of the energy loop" at Gössis something that Andreas, Heineken and all of its 150 employees can be most proud of. As while there are still improvements to be made, this brewery is, seemingly, streets ahead of its competitors when it comes down to sustainability in brewing beer.

Some may argue that Göss isa Goldilocks scenario, where all the conditions and people have fallen together at just the right moment and in the perfect environment to generate sustainable success, however, while there is probably some truth in that statement, from what we saw and heard we certainly don't feel that the environmental benefits enjoyed here couldn't be elsewhere.

Beer produced in theGöss brewery is pumped into delivery tankers at a rapid rate, like a car being filled up with fuel

The key, as demonstrated inGöss well, is that you have to have the will to make the change both on a macro and micro level, the financial investment in the sustainable technologies and, of course, some sound business nous and acumen to engage with beneficial industries and local institutions.

Göss has done this and, hopefully, can build even further on its carbon-neutral status to become even more environmentally friendly.

Couldn't resist!

So, all in all, T3 had a top time vistingGöss. It was fascinating to see howGösser beer was produced, how it was done so with advanced sustainable technologies and, crucially, how you should drink it, which we did lots of.

Seriously, we drank A LOT of good beer.

Cheers!

Rob has been writing about computing, gaming, mobile, home entertainment technology, toys (specifically Lego and board games), smart home and more for over 15 years. As the editor of PC Gamer, and former Deputy Editor for T3.com, you can find Rob's work in magazines, bookazines and online, as well as on podcasts and videos, too. Outside of his work Rob is passionate about motorbikes, skiing/snowboarding and team sports, with football and cricket his two favourites.